There are several types of plastic recycling but all of them have the same steps they must complete prior to offering recycled plastic materials for sale.

All must have a collection system, sorting, purification, & conversion.

So, what are the different types of recycling? Let us discuss each one.

1. Mechanical Recycling

2. Chemical Recycling

3. Chemical Washing

MECHANICAL RECYCLING

Mechanical recycling is the most common and tends to be the most known among the three different recycling process. Following the process all plastic recycling undergoes, the plastic is collected through several different means such as curbside pickup from your home. From here, the materials go through a sorting process that employs both human and machine sorting of the materials into the different group’s plastics are recycled.

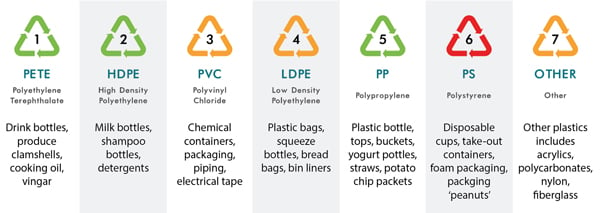

These different groups are sorted based on the recycle codes 1 through 6 with number 7 typically going to the landfill or used for waste to energy. As a refresher here are the seven recycle codes.

There are many ways materials are sorted. Recyclers utilize humans to sort, NIR detection, magnets, gravity/float process and cameras to sort one material from another and remove contaminates such as metal.

Once the materials have been sorted on a large scale, the materials will be mechanically shredded or ground to smaller more manageable sizes. In some cases, the material will be sorted an additional time to ensure the highest level of confidence that the materials are sorted properly.

Now that the materials are sorted the plastic must be washed. To be clear, the mechanical recycling process washes the surface of the material. Depending on the type of material or the source of the material, several washings will be done to not only clean the material but also to remove any bad smells the material may have picked up during the use, collection, and sorting process.

The material is now ready to be processed back into a pellet. The sorted and washed material is then fed into an extrusion machine to be melted and converted into a pellet. During this process a lab sample will be taken to check properties such as melt flow, flex modulus and check for non-desirable materials such as heavy metals. If the properties are not up to standard, different lots of the same material may be introduced to bring the properties back into line. Virgin additives may be used to bring properties up or accentuate one particular property desired. Once the material reaches the desired properties the material will continue to be extruded and pellets formed for sale. The step prior to selling the material will be a post blend of the entire lot to ensure the entire lot is the same throughout the entire run.

Once the material reaches the desired properties the material will continue to be extruded and pellets formed for sale. The step prior to selling the material will be a post blend of the entire lot to ensure the entire lot is the same throughout the entire run.

CHEMICAL RECYCLING

Chemical recycling is another process used to provide plastic materials in a recycled form. Chemical recycling just like mechanical recycling, utilizes many if not all the mentioned sorting protocols to ensure that when it is time to convert from raw recycle to finished recycle.

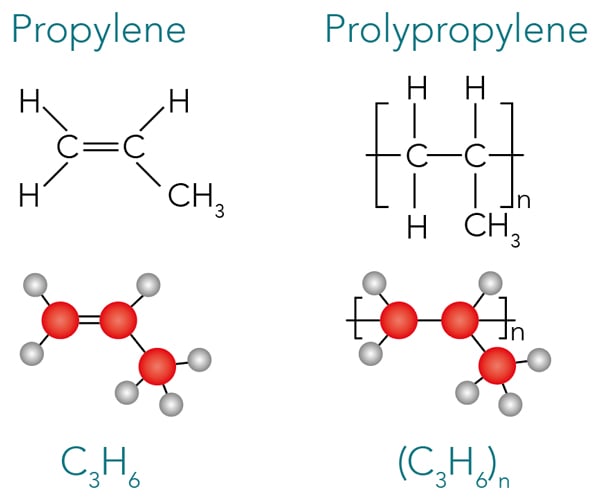

After the material is sorted, the material broken down by either using chemicals or the use of Pyrolysis & Gasification. In layman’s terms, plastic is broken down into its basic form of plastic monomers, intermediate chemicals and contaminants.

In the plastics industry, we would refer to this as unzipping the polymer chain. In this state, it is much easier to remove contaminants which can include fungus, mold, color, etc. Once filtered, the remaining chemicals can now essentially be put back together to recreate the polymer in a completely clean virgin-type state.

Chemical recycling is preferred by most converters due to material consistency, properties and cleanliness.

CHEMICAL WASHING

Chemical washing follows the same course as mechanical and chemical recycling for sorting to prepare the materials for conversion to a usable product by converters. Where this type of recycling diverges from the other two, the process utilizes chemicals to clean and purify the plastic without changing or breaking down the polymer into different monomers. Essentially, it remains the same plastic from start to finish like mechanical recycling.

Once the material is washed, it will be extruded, tested, and then extruded into a pellet for resale.

CONCLUSION

Understanding the differences in plastic recycling methods allows for informed choices based on what your product requires. Many understand mechanical recycling. Chemical recycling and chemical washing, on the other hand, are sometimes thought of as the same type of recycling when in fact they are very different and provide different results in the end.

Chemical recycling is gaining ground due to the purity of the pellet, the properties attained and the ease of conversion for the processor. There are limitations in the market as it grows with higher-end materials being some of the first to be offered. As the technology grows, innovations regarding speed and costs are driven down, allowing us to see the commodity resin market start to offer more and more chemical recycle.